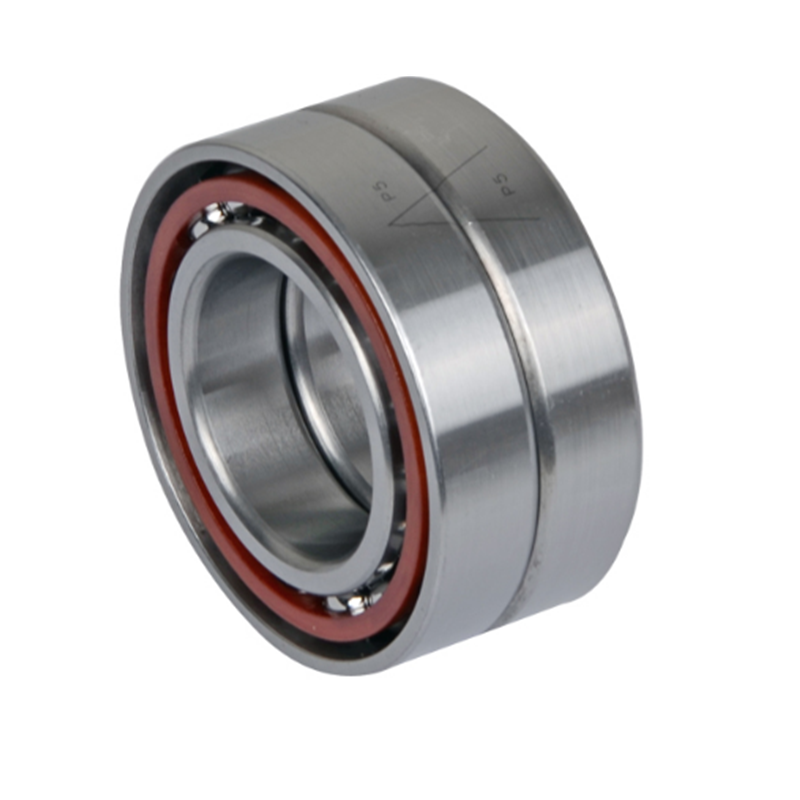

Angular contact ball bearing feature :

1) Bear radial load and axial load 2) The larger the contact angle, the higher the axial bearing capacity 3) Advanced grade technology 4) Quiet and smooth operation even at high speed 5) Super finished raceways 6) Offer products in 15,25 and 40 degree angles

Angular contact ball bearings can be used for: Machine tool spindles, high frequency motors, gas turbines, centrifuges, small car front wheel, differential pinion shaft, boosterpumps, drilling rigs, food machinery, dividing heads, fill welding, low-noise cooling tower

Angular contact thrust ball bearing for ball screw support(machine tool applications) brand ball screw Angle contact ball bearing brand 25TAC62BSBC10PN7A bearing 25---the size of the inner diameter (mm) TAC---thrust Angle contact ball bearing, the contact Angle is 60 ° 62---the size of the outer diameter (mm) B---internal style DF---a combination SU---free combination (single) DU---free combination (2 column) DB---back-to-back combination DF---face to face combination DT---tied for combination DBD DFD DTD---3 columns combination DBB DFF DBT DFT DTT---4 columns combination C10---standard preloaded C9---light preloaded | low torque style PN7A---standard precision (equivalent to ISO4 class) PN7B---inside outside diameter size difference special control precision (equivalent to ISO4 grade, SU combination special). Angular contact ball bearing include: 1) Single row angular contact ball bearing 2) Matched angular contact ball bearing 3) Double row angular contact ball bearing 4) Four-point contact ball bearing Angular contact ball bearings features : 1) Load capacities are higher than deep groove ball bearings of same dimensions; 2) Used for bearing radial-axial combined loads or pure thrust loads; 3) Low operating friction and high limiting speed.

| Model Number | Dimension (mm) | Load | Speed | KG | ||||||||

| d | D | B | rsmin | r1smin | a | Cr | Cor | Kg | ||||

| mm | ≈ | KN | r/min | ≈ | ||||||||

| 7004C | 20 | 42 | 12 | 0.60 | 0.15 | 10 | 9.6 | 6.3 | 38000 | 56000 | 0.06 | |

| 7004AC | 20 | 42 | 12 | 0.60 | 0.15 | 13 | 9.2 | 6.0 | 34000 | 50000 | 0.06 | |

| 7005C | 25 | 47 | 12 | 0.60 | 0.15 | 11 | 12.9 | 8.7 | 34000 | 50000 | 0.07 | |

| 7005AC | 25 | 47 | 12 | 0.60 | 0.15 | 14 | 12.3 | 8.3 | 30000 | 45000 | 0.07 | |

| 7006C | 30 | 55 | 13 | 1.00 | 0.30 | 12 | 15.7 | 11.6 | 28000 | 43000 | 0.11 | |

| 7006AC | 30 | 55 | 13 | 1.00 | 0.30 | 17 | 14.9 | 10.9 | 24000 | 38000 | 0.11 | |

| 7007C | 35 | 62 | 14 | 1.00 | 0.30 | 13 | 19.3 | 17.5 | 20000 | 34000 | 0.15 | |

| 7007AC | 35 | 62 | 14 | 1.00 | 0.30 | 18 | 18.3 | 16.6 | 19000 | 32000 | 0.15 | |

| 7008C | 40 | 68 | 15 | 1.00 | 0.30 | 15 | 19.9 | 19.1 | 19000 | 32000 | 0.19 | |

| 7008AC | 40 | 68 | 15 | 1.00 | 0.30 | 20 | 18.9 | 18.2 | 17000 | 28000 | 0.19 | |

| 7009C | 45 | 75 | 16 | 1.00 | 0.30 | 16 | 26.7 | 25.3 | 17000 | 28000 | 0.23 | |

| 7009AC | 45 | 75 | 16 | 1.00 | 0.30 | 22 | 25.4 | 24.1 | 16000 | 26000 | 0.23 | |

| 7010C | 50 | 80 | 16 | 1.00 | 0.30 | 17 | 27.6 | 27.5 | 16000 | 26000 | 0.25 | |

| 7010AC | 50 | 80 | 16 | 1.00 | 0.30 | 23 | 26.2 | 26.2 | 15000 | 24000 | 0.25 | |

| 7011C | 55 | 90 | 18 | 1.10 | 0.60 | 19 | 36.7 | 37.1 | 14000 | 22000 | 0.37 | |

| 7011AC | 55 | 90 | 18 | 1.10 | 0.60 | 26 | 34.8 | 35.3 | 13000 | 20000 | 0.37 | |

| 7012C | 60 | 95 | 18 | 1.10 | 0.60 | 19 | 37.8 | 40.0 | 14000 | 22000 | 0.39 | |

| 7012AC | 60 | 95 | 18 | 1.10 | 0.60 | 27 | 35.8 | 38.0 | 12000 | 19000 | 0.39 | |

| 7013C | 65 | 100 | 18 | 1.10 | 0.60 | 20 | 38.9 | 42.9 | 13000 | 20000 | 0.42 | |

| 7013AC | 65 | 100 | 18 | 1.10 | 0.60 | 28 | 36.8 | 40.7 | 11000 | 18000 | 0.42 | |

| 7014C | 70 | 110 | 20 | 1.10 | 0.60 | 22 | 49.9 | 55.5 | 12000 | 19000 | 0.59 | |

| 7014AC | 70 | 110 | 20 | 1.10 | 0.60 | 31 | 47.2 | 52.7 | 10000 | 17000 | 0.59 | |

| 7015C | 75 | 115 | 20 | 1.10 | 0.60 | 23 | 51.3 | 59.2 | 11000 | 18000 | 0.62 | |

| 7015AC | 75 | 115 | 20 | 1.10 | 0.60 | 32 | 48.5 | 56.2 | 9500 | 16000 | 0.62 | |

| 7016C | 80 | 125 | 22 | 1.10 | 0.60 | 25 | 61.6 | 70.4 | 10000 | 17000 | 0.83 | |

| 7016AC | 80 | 125 | 22 | 1.10 | 0.60 | 35 | 58.3 | 66.9 | 9000 | 15000 | 0.83 | |

| 7017C | 85 | 130 | 22 | 1.10 | 0.60 | 25 | 63.3 | 75.0 | 9500 | 16000 | 0.87 | |

| 7017AC | 85 | 130 | 22 | 1.10 | 0.60 | 36 | 59.9 | 71.3 | 8500 | 14000 | 0.87 | |

| 7018C | 90 | 140 | 24 | 1.50 | 0.60 | 27 | 66.9 | 84.0 | 9000 | 15000 | 1.18 | |

| 7018AC | 90 | 140 | 24 | 1.50 | 0.60 | 39 | 63.2 | 79.7 | 8000 | 13000 | 1.18 | |

| 7019C | 95 | 145 | 24 | 1.50 | 0.60 | 28 | 79.1 | 97.6 | 8500 | 14000 | 1.2 | |

| 7019AC | 95 | 145 | 24 | 1.50 | 0.60 | 40 | 74.8 | 92.7 | 7500 | 12000 | 1.2 | |

| 7020C | 100 | 150 | 24 | 1.50 | 0.60 | 29 | 81.2 | 103.3 | 8000 | 13000 | 1.25 | |

| 7020AC | 100 | 150 | 24 | 1.50 | 0.60 | 41 | 76.7 | 98.0 | 7000 | 11000 | 1.25 | |

| 7021C | 105 | 160 | 26 | 2.00 | 1.00 | 31 | 93.9 | 118.2 | 7500 | 12000 | 1.58 | |

| 7021AC | 105 | 160 | 26 | 2.00 | 1.00 | 44 | 88.8 | 112.2 | 7000 | 11000 | 1.58 | |

| 7022C | 110 | 170 | 28 | 2.00 | 1.00 | 33 | 110.4 | 139.8 | 7000 | 11000 | 1.97 | |

| 7022AC | 110 | 170 | 28 | 2.00 | 1.00 | 47 | 104.4 | 132.8 | 6700 | 10000 | 1.97 | |

| 7024C | 120 | 180 | 28 | 2.00 | 1.00 | 34 | 112.7 | 148.7 | 7000 | 11000 | 2.11 | |

| 7024AC | 120 | 180 | 28 | 2.00 | 1.00 | 49 | 106.5 | 141.1 | 6700 | 10000 | 2.11 | |

| 7026C | 130 | 200 | 33 | 2.00 | 1.00 | 39 | 144.8 | 190.8 | 6700 | 10000 | 3.18 | |

| 7026AC | 130 | 200 | 33 | 2.00 | 1.00 | 55 | 136.8 | 181.0 | 6000 | 9000 | 3.18 | |

| 7028C | 140 | 210 | 33 | 2.00 | 1.00 | 40 | 148.7 | 202.6 | 6000 | 9000 | 3.37 | |

| 7028AC | 140 | 210 | 33 | 2.00 | 1.00 | 57 | 140.4 | 192.2 | 5600 | 8500 | 3.37 | |

| 7030C | 150 | 225 | 35 | 2.10 | 1.10 | 43 | 168.4 | 232.5 | 5600 | 8500 | 4.1 | |

| 7030AC | 150 | 225 | 35 | 2.10 | 1.10 | 61 | 159.1 | 220.6 | 5000 | 7500 | 4.1 | |

| 7032C | 160 | 240 | 38 | 2.10 | 1.10 | 46 | 189.1 | 264.5 | 5000 | 7500 | 5.07 | |

| 7032AC | 160 | 240 | 38 | 2.10 | 1.10 | 66 | 178.6 | 251.0 | 4800 | 7000 | 5.07 | |

| 7034C | 170 | 260 | 42 | 2.10 | 1.10 | 50 | 205.6 | 299.3 | 4800 | 7000 | 6.9 | |

| 7034AC | 170 | 260 | 42 | 2.10 | 1.10 | 71 | 194.2 | 284.0 | 4300 | 6300 | 6.9 | |